Metal fabrication is a critical process in industries ranging from automotive to aerospace. Achieving accuracy and efficiency is essential to ensure high-quality products. Traditional methods of cutting and shaping metals often involve slower processes and can sometimes compromise precision. However, with the introduction of advanced technologies like the fiber laser, manufacturers can achieve unprecedented accuracy and efficiency. Fiber lasers have become a game-changer in metal fabrication, offering precise control and consistent results.

Understanding Fiber Lasers

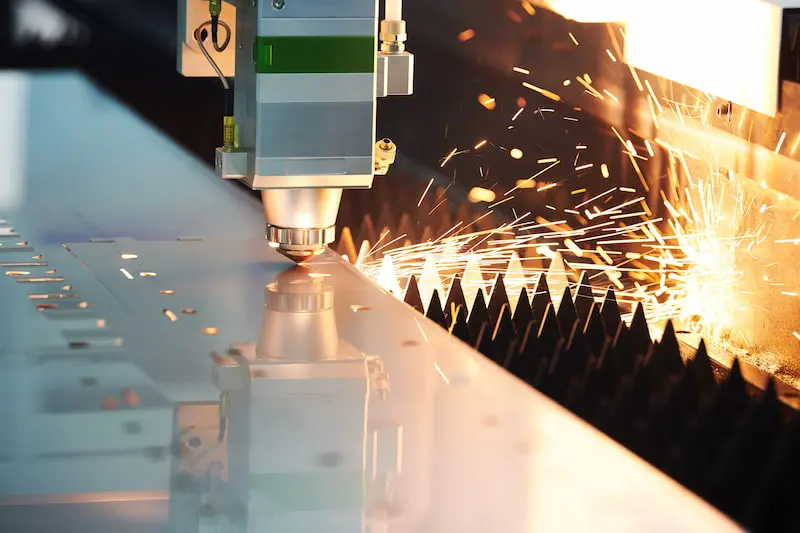

A fiber laser is a type of laser that uses optical fibers doped with rare-earth elements to generate a concentrated beam of light. This beam is highly focused and can be directed with great accuracy. Unlike traditional CO2 lasers, fiber lasers are more energy-efficient and require less maintenance. They also produce a smaller heat-affected zone, which reduces the risk of warping or damaging the metal during cutting or engraving. This makes fiber lasers ideal for applications where precision is critical.

Enhanced Cutting Precision

One of the primary advantages of using a fiber laser in metal fabrication is the ability to achieve highly precise cuts. The concentrated laser beam allows manufacturers to cut complex shapes with minimal tolerance errors. Whether it’s thin sheets of stainless steel or thicker aluminum plates, a fiber laser can deliver smooth and clean edges. This level of precision reduces the need for secondary finishing processes, saving both time and resources. For industries where exact measurements are essential, such as medical device manufacturing or aerospace parts production, fiber lasers ensure that components meet strict quality standards.

Faster Production and Efficiency

Fiber lasers not only improve precision but also enhance production speed. The high power and efficiency of the fiber laser allow metals to be cut quickly without compromising accuracy. This speed is particularly beneficial in large-scale manufacturing environments where meeting tight deadlines is crucial. Additionally, fiber lasers are capable of cutting multiple layers of metal at once, further increasing productivity. Manufacturers can produce more parts in less time while maintaining a high level of detail, making fiber lasers an economically advantageous choice.

Minimal Material Waste

Precision in metal fabrication also means reduced material waste. Traditional cutting methods can result in uneven edges and excess scrap material, increasing costs and environmental impact. Fiber lasers, with their pinpoint accuracy, ensure that cuts are exact and consistent. This minimizes errors and allows manufacturers to make the most out of every sheet of metal. By reducing waste, companies can lower production costs and support sustainable manufacturing practices.

Versatility in Applications

Fiber lasers are versatile tools that can handle a wide range of metals, including steel, aluminum, copper, and brass. They are not limited to cutting; fiber lasers can also be used for engraving, marking, and drilling metals with exceptional precision. This versatility makes fiber lasers a valuable investment for metal fabrication shops that need to handle diverse projects. Whether producing industrial machinery, decorative metalwork, or precision components, fiber lasers provide the flexibility to achieve high-quality results across different applications.

Consistent Quality and Reliability

Another significant advantage of fiber lasers is the consistency of their performance. Unlike mechanical cutting tools that may wear down over time, a fiber laser maintains its precision throughout long production runs. This reliability ensures that every part meets the same high standard, reducing the likelihood of defects and rework. Consistent quality is essential for businesses that supply critical components where failure is not an option. Fiber lasers give manufacturers confidence that their products will meet both customer expectations and industry regulations.

Conclusion

In modern metal fabrication, precision, efficiency, and reliability are more important than ever. Fiber lasers have revolutionized the way metals are cut, engraved, and shaped, offering unparalleled accuracy and speed. By reducing material waste, improving production efficiency, and delivering consistent results, fiber lasers have become an indispensable tool for manufacturers. For businesses looking to enhance their metal fabrication processes, investing in fiber laser technology is a strategic move that ensures high-quality outcomes and long-term operational benefits.